2D drawings can be a bit of a handful to work with. When you have multiple 2D drawings of the same product, all of the planes can be stacked on top of one another. This makes it very difficult to create accurate 2D drawings, which is a real pain when you’re trying to show off the key features of the part you’re trying to build.

2D drawings can be a bit of a handful to work with. When you have multiple 2D drawings of the same product, all of the planes can be stacked on top of one another. This makes it very difficult to create accurate 2D drawings, which is a real pain when you’re trying to show off the key features of the part you’re trying to build.

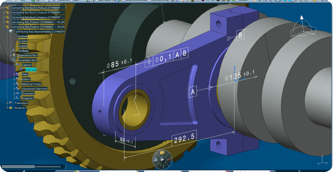

Today, 90% of manufacturing companies still use 2D drawings as the main reference point for dimensions, tolerances and annotations. Yet when design changes need to be made to the 2D drawing and the parts list, these datasets may go out of sync with each other leading to costly delays in product development. And before you know it, one of your competitors has launched a new product onto the market. But this is where CATIA 3D Master can save you a lot of time and money. The CATIA 3D Master Approach enables users to create and annotate 3D drawings in a single geometrical file, which can be easily shared across your organization for downstream processes.

Still not convinced? Well here’s 3 ways CATIA 3D Master can improve your product development.

3D vs 2D

Although 2D drawings are important in tolerancing and annotations, having to deal with sheets upon sheets of drawings to understand the dimensions of a single part is enough to drive anyone mad.

The CATIA 3D Master Approach simplifies all of this through the creation of a single geometrical file that comprises of the dimensions, annotations and tolerances of a part. What’s more, this single file can be shared throughout your organization with annotated notes to aid the understanding of, say, the marketing department for activities that occur downstream.

Increasing everyone’s understanding of the development of a part from a single reference point can work wonders for speeding up the product development process.

3D drawings also hold an important advantage over 2D drawings when it comes to understanding design standards on a global scale. That’s right, global. Heaps of 2D drawings can contain annotations that are not so easily understood overseas, compared to a single 3D drawing.

So if you’re working with people across the world, you want to be sure that everyone can understand the part you’re working with – so why not do that with a single 3D design?

But if you’re worried about learning how to use CATIA 3D Master, don’t sweat. If you already have an understanding of how to create 2D drawings, you can learn how to create them in 3D in just a day and half. Short training in Functional Tolerancing and Annotation (FT&A) will turn you into a Master of CATIA 3D Master.

Improve ROI

If you’re conscious about making sure that your business doesn’t waste money in product development, then CATIA 3D Master is right for you.

CATIA 3D Master can help to improve your manufacturing process definition and data exchange by simply cutting down the number of drawings you need to make, into a single and simple file.

The advantages of a single geometrical file also extend beyond process definition benefits. Having all of your annotations, dimensions, tolerances and parts list neatly packaged in a single file reduces the chances of these datasets falling out of sync.

Ultimately, this speeds up the product development process and equally cuts costs, ensuring your product can reach the market quicker and at a cheaper cost to your organization. Quite simple really.

And if that wasn’t enough, CATIA 3D Master also allows you to conduct Simulations of your builds where you can check to see if dimensional requirements are met. These Simulations may also allow you to loosen tolerances in the part, reducing the cost of manufacturing by as much as 90%!

Improve Productivity

And last but not least, CATIA 3D Master has the ability to improve your productivity. By creating a single 3D reference point with 100% of the product definition, you can re-use this product definition for product families or the development of future products.

Moreover, the creation of a single file allows you to more accurately create a drawing for a part, reducing the chances for errors. This is compared to the mounting errors that can occur in 2D drawings where consistency needs to be maintained across numerous drawings.

Essentially, having fewer errors means a quicker production process, which also helps to cut down costs.

So to sum up, CATIA 3D Master can improve your product development by;

- Increasing the understanding of the drawing of the part across departments

- Increasing ROI through cutting manufacturing costs and time to market

- Improving productivity by allowing re-use of the product definition in future builds.

And that’s 3 reasons how the CATIA 3D Master can improve your product development. But if you’re still not sure quite what to think, check out the whitepaper ‘CATIA 3D Master – Driving Accuracy into Your Business’ for more information on how CATIA 3D Master can benefit your organization.

.png?width=139&height=70&name=DTE-Logo%20(4).png)