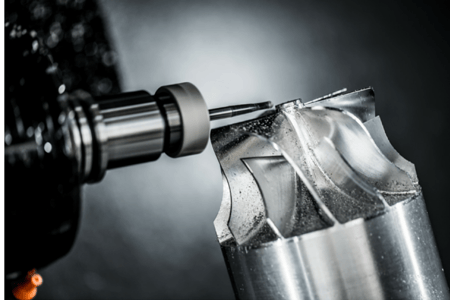

CATIA Manufacturing (V5 or 3DEXPERIENCE) offers a complete CAD/CAM solution for a multitude of industrial applications in a fully homogenous environment.

CATIA Manufacturing (V5 or 3DEXPERIENCE) offers a complete CAD/CAM solution for a multitude of industrial applications in a fully homogenous environment.

The programming tools CATIA offer are highly powerful and industry leading on both the manufacturing and design side. However, unless this powerful functionality is being sufficiently leveraged, the investment is not being capitalized on.

Let’s have a look at just 3 CATIA functions, that if implemented correctly, will very quickly bring about some noteworthy benefits and address key areas that have become buzz words within manufacturing –

‘The Skills Shortage’, Automation, Standardisation:

1. Power Copy

Power Copy is used within the design environment and is essentially a re-use and automation tool. By using Power Copy, it is easy to standardise how certain features are created in a fast and efficient manner.

Power Copy is used within the design environment and is essentially a re-use and automation tool. By using Power Copy, it is easy to standardise how certain features are created in a fast and efficient manner.

A great example of Power Copy use is in aerostructure programming where parts can reach >20m in length and programmers often repetitively create large amounts of NC geometry to perfect and fully optimize the cutting path.

2. Process Catalogues

Process Catalogues are used within the NC programming environment and are another re-use and automation tool. This function provides a method to standardise processes whether that be for individual tool paths or programming entire part families.

Process Catalogues are used within the NC programming environment and are another re-use and automation tool. This function provides a method to standardise processes whether that be for individual tool paths or programming entire part families.

In the case of the latter, any number of pre-defined tool paths with the appropriate parameter settings and cutting tools can be instantiated into the programming session with a few clicks of the mouse.

3. Tool Catalogues

Tool catalogues offer an excellent way to organise cutting tool assemblies, so the NC team all have access to the same data. The tool catalogue stores every piece of information the programmer needs without having to use ‘best guesses’ at speed, feeds, DOC etc.

Tool catalogues offer an excellent way to organise cutting tool assemblies, so the NC team all have access to the same data. The tool catalogue stores every piece of information the programmer needs without having to use ‘best guesses’ at speed, feeds, DOC etc.

Company knowledge can easily be captured, standardised and re-used.

Commonly an implementation of the above tools would show an immediate positive impact in relation to the following:

- Improved ROI on software

- Standardized approach and output from every programmer on the team

- Reduced lead times/bottlenecks on NC programming

- Reduced cycle times

- Reduced learning curve for new programmers

An implementation of these types of automation tools at one OEM yielded an NC programming time reduction of 60%.

Get in touch with the DTE team to understand how we can help you get the most from CATIA.

.png?width=139&height=70&name=DTE-Logo%20(4).png)