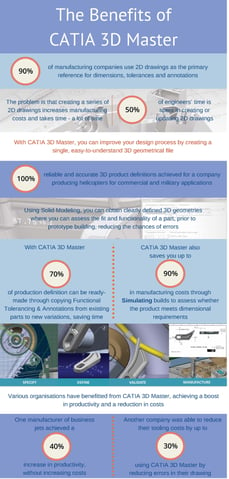

For a long time 2D drawings have been central to the product development process. Yet 2D drawings also have their flaws, often producing errors in design and contributing to higher manufacturing costs. That’s where the CATIA 3D Master concept is able to help.

For a long time 2D drawings have been central to the product development process. Yet 2D drawings also have their flaws, often producing errors in design and contributing to higher manufacturing costs. That’s where the CATIA 3D Master concept is able to help.

The CATIA 3D Master approach enables various departments within a company to share, annotate and improve product design using the 3D format. This approach yields numerous benefits, including boosting accuracy in design, improving decision-making and improving efficiency in design.

Increased design accuracy

Within 2D drawings, changes to designs mean these alterations need to be applied to the solid model, the parts list and the 2D drawing. The difficulty is that applying these changes can often cause these datasets to go out of sync with each other.

Creating a series of 2D drawings to describe a single and often complex 3D part can complicate the situation further. Trying to determine the specifications of a 3D part using multiple 2D drawings can lead to misunderstandings in design, ultimately leading to the creation of poor parts.

Using the CATIA 3D Master approach, these difficulties can be avoided. The CATIA 3D Master approach enables users to group all design elements into a single 3D geometrical file, eliminating the chances for data to fall out of sync with each other. This enables collaboration on design across departmental teams while reducing the chances for misunderstanding in product design.

The CATIA 3D Master approach also offers a tolerancing advisor, aiding the user in applying geometrical tolerances to a part while preventing the creation of an invalid tolerance. This helps to ensure accuracy in the structural design, boosting the integrity of the design of the part.

Improved decision-making

Working from a single 3D geometrical file also has benefits when it comes to decision-making.

Teams are able to view, change and collaborate on product design in real-time. By gaining insight into dimensioning and tolerancing annotations and geometrical elements early in the process, teams are well-placed to make better decisions concerning design.

Efficiency in design

The CATIA 3D Master approach also helps to increase the efficiency of your approach to product design, particularly for potential future versions/updates of your product.

The CATIA 3D Master approach enables you to re-use product definition information including tolerancing and annotations for application to future versions of a product. You can even create templates that contain tolerancing and annotations for use in future projects, automating elements of the product development process.

Simulating build variations also achieves efficiency in design. Using simulation, you have the ability to loosen tolerances and ultimately assess if the product meets dimensional requirements. By loosening tolerances, you can even achieve cost reductions in your manufacturing by up to 90%.

Overall, the CATIA 3D Master approach is able to improve your approach to structural design by;

- Increasing design accuracy by collating all design elements into a single 3D geometrical file

- Improve decision making by enabling teams to collaborate in real-time on product design

- Boosting efficiency in design by allowing simulation of build variations and re-use of product definitions for future versions of your product.

To learn more about the benefits of a 3D design approach, read the whitepaper ‘CATIA 3D Master – Driving Accuracy into Your Business’ and discover how we can help you to improve your drawings and increase your product quality.

.png?width=139&height=70&name=DTE-Logo%20(4).png)