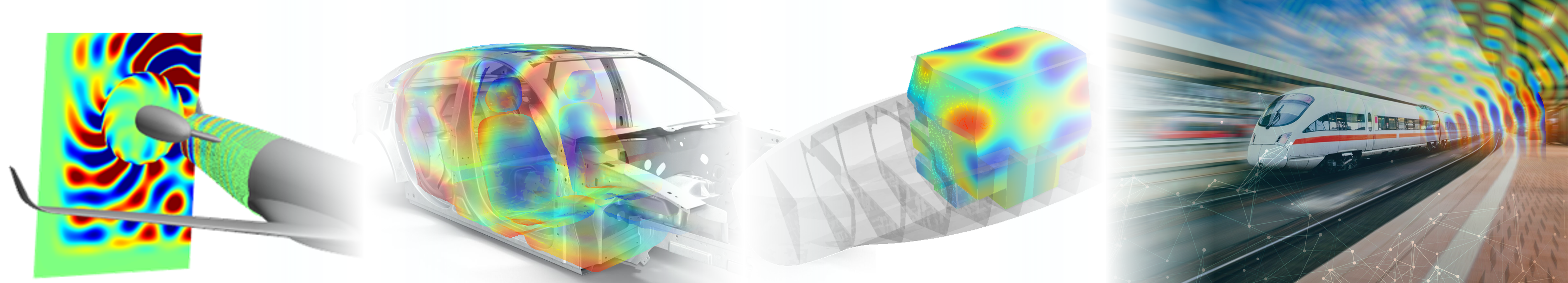

Actran Diffuse Sound Field (DSF) demo

Actran, from MSC Software, is an acoustics simulation software, originally designed for predicting noise within, and around vehicles, such as cars and aircraft.

Topics: Various - CAD CAM FEA PLM, Finite Element Analysis (FEA), Aerospace, Hexagon MSC Software, space techologies

Space Technologies - solutions with Heritage

NASA Structural Analysis Code* was just the beginning .....

MSC Software has been a key partner to the Space Industry since the 1960s. Many people associate MSC only with Nastran, which is the keystone of their product set, but through a process of development and acquisition, they have developed a portfolio of tools that are used across a number of domains within engineering simulation in the Space Industry.

Topics: Finite Element Analysis (FEA), Aerospace, Hexagon MSC Software, space techologies

New Space ... New Horizons

New Space – the commercial space industry driven by private organizations – is making giant leaps in space tourism, exploration and satellite technology. Europe, the USA, China, India and Israel are among the countries that stand to gain as innovative projects promise benefits such as insights into weather patterns and climate change, better communications networks, and geographical data analytics to help farmers improve crop yields.

Topics: Aerospace, #HowCanWeHelpYou?, space techologies

Live Online Training in 3DEXPERIENCE delivered

15 delegates all connected from home

Just 3 days after launching our Live Online training portal, DTE has successfully delivered its first course to 15 delegates.

Engineers from Vertical Aerospace, the British eVTOL company, joined with DTE consultant Neil Watford, on a day’s session on Change Management using Dassault’s 3DEXPERIENCE On-Cloud platform.

All delegates praised the format, commenting that it was easy to join, access the training collateral and interact with the trainer.

Topics: 3DEXPERIENCE, Dassault Systemes, Aerospace, Training, CATIA

Benefits of CATIA for Composite Design & Manufacturing

Paying attention to the careful design and material selection guidelines in the design and manufacturing of composites is vital to ensuring structural integrity of parts. Without adherence to guidelines in designing composites, this can lead to the development of poor quality parts, which isn’t going to help anyone.

This is extremely important as the benefits of strong composite designs include the production of lightweight, impact resistant and strong parts compared to standard metal products. Ultimately, this leads to the manufacturing of better quality parts for a better quality product, especially when these parts will be used in aircrafts where safety protocols are extremely stringent.

The production of better quality parts is also important due to Governmental crackdowns on carbon emissions, particularly for aircrafts. But with composite design, the reduction in fuel costs and carbon emissions based on the production of lightweight structures helps to adhere to Governmental pressures.

Topics: Aerospace

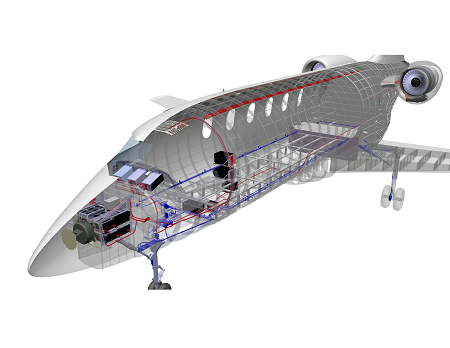

How to Manage Aerospace Supply Chains using Software

A commercial jet aircraft has millions of individual parts and a supply chain that covers multiple tiers, from raw materials to the finished product.

It’s the supply chain that can be spread across numerous companies globally, specialising in different parts and components. To complicate things further, each component might be part of a subset that is being developed by a different supplier, and so compatibility issues between parts may surface.

With such a complex supply chain it’s easy for things to wrong, especially when you consider the thousands of people who might be involved in the development of a new aircraft.

By using a software package that improves communication, eliminates design and development errors, speeds up time to market and reduces costs along the way, managing the supply chain becomes much more efficient.

Topics: 3DEXPERIENCE, Dassault Systemes, Aerospace, CATIA

Benefits of 3DEXPERIENCE CATIA for Composite Design & Manufacturing

Paying attention to the careful design and material selection guidelines in the design and manufacturing of composites is vital to ensuring structural integrity of parts. Without adherence to guidelines in designing composites, this can lead to the development of poor-quality parts, which isn’t going to help anyone.

This is extremely important as the benefits of strong composite designs include the production of lightweight, impact resistant and strong parts compared to standard metal products. Ultimately, this leads to the manufacturing of better quality parts for a better-quality product, especially when these parts will be used in aircraft where safety protocols are extremely stringent.

The production of better-quality parts is also important due to Governmental crackdowns on carbon emissions, particularly for aircrafts. But with composite design, the reduction in fuel costs and carbon emissions based on the production of lightweight structures helps to adhere to Governmental pressures.

Topics: 3DEXPERIENCE, Various - CAD CAM FEA PLM, Aerospace, CATIA

Boeing 737 MAX – The case for Instructor-led Training

The current issue over the recent crashes of two Boeing 737 MAX aircraft has uncovered many issues over the design, certification and operation of this new aircraft.

The importance of composites in Aerospace & Automotive industries

Raise your hand if you’ve ever sat down and asked yourself ‘what can we do to improve our product quality?’ but struggled to find the most cost-effective way to do this.

As the complexity of product designs increases, so too does the need to find the right materials and techniques to bring these designs to life. This is where composite materials come into their own.

Here’s how your organisation can benefit from the use of composite materials and how the aerospace and automotive industries are making strides in the use of composites.

Topics: Automotive, ICAM Technologies, Aerospace

Understanding the risks in the aerospace supply chain

As consumers around the world are demanding greater access to air travel, this has led to orders for 38,000 new aircraft. Although this represents the potential for significant revenue, OEMs and suppliers face significant risks that they must overcome in order to develop these aircraft cost effectively and ensure a quick time to market.

A major trigger of these risks is how OEMs are now tasking suppliers with designing aerospace parts in addition to manufacturing.

Topics: Various - CAD CAM FEA PLM, Aerospace

.png?width=139&height=70&name=DTE-Logo%20(4).png)