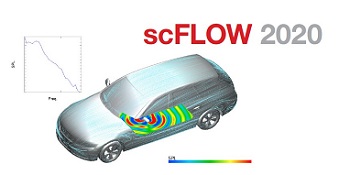

scFLOW Simulation Demo

Next generation CFD tool

scFLOW from MSC Software is a state-of the art Computational Fluid Dynamic (CFD) package which uses a polyhedral mesh to solve some very complex problems with short run-times that have surprised long term users of other CFD packages.

Topics: Various - CAD CAM FEA PLM, Finite Element Analysis (FEA), Computational Fluid Dynamics (CFD), Hexagon MSC Software, CAE Tools

Electronics Cooling with scSTREAM

scSTREAM is one of the newest products in the MSC Software portfolio.

It aims to make the job of simulating fluid flow and heat transfer easy and accessible to more Engineers than traditional Computational Fluid Dynamic (CFD) packages.

The movie below shows a quick demonstration of its use for a simple thermal assessment of a small electronics package.

Topics: Finite Element Analysis (FEA), Computational Fluid Dynamics (CFD), Hexagon MSC Software

Defeaturing with MSC Apex

Prepping Computer-Aided Design (CAD) geometry for Finite Element Analysis (FEA) can be a complex, time-consuming and error-prone activity.

MSC Apex has been designed from the ground-up to make this a simple and intuitive step that can dramatically reduce the time spent in this part of the process, freeing highly qualified engineers to do more analysis and design improvement.

Topics: Various - CAD CAM FEA PLM, Finite Element Analysis (FEA), Hexagon MSC Software

Zoom Modelling with MSC Marc

One of the parameters driving the age-old question of “is my mesh refined enough?” is the impact it has on the model size and the knock-on effect to runtime and computer spec. This comes into starkest relief if you have a dimensionally very large structure but where you need a fine local mesh around some detailed areas in order to refine stress intensity for e.g. fatigue life prediction.

Meshing Irregular Parts in Hex Elements

Almost all the solid element meshes I come across in the last decade or so have used second-order 10 noded tetrahedral elements, and for most applications, they are perfectly fine. There are however some applications in some FEA solvers that require a hex8 element – for example some elastomer models, magneto and electrostatic solvers, and some acoustic solutions. How do you mesh an irregular part in hex elements?

Composite Zoning Optimisation

It is for good reasons that designing laminated composite structures is sometimes known as a ‘black art’. It is not easy to intuit from the topology of and loads applied to a component what a good ply layup should be. Many companies rely on the wisdom of veteran engineers’ hard-won experience, but sometimes it is necessary to take a step back and ask “what else could we try?”.

Often the design of a composite layup starts with the definition of zones within a part. The layup on each of these zones can then be fettled using FEA to arrive at a stacking sequence which can then be used to define plies.

But how do you choose the zones? Is it arbitrary based on the topology of the part? Do you just chequer-board your panel into regular squares? You could use a technique developed with MSC Nastran for one of the F1 companies.

Topics: Various - CAD CAM FEA PLM, Finite Element Analysis (FEA), Hexagon MSC Software

Fracture Mechanics

Modelling Cracks the Easy Way

In my previous blog I talked about the advantages of automatic re-meshing in the analysis of rubbers in improving accuracy and stability of a simulation. One advanced application of this capability that was not touched upon was in the field of crack propagation.

In many industries it is sufficient to use your analysis to predict that a crack could initiate and redesign the part to avoid this occurrence. In others though it is possible that a crack may be identified from an in-service inspection whereupon it becomes necessary to understand if it will propagate under the loads applied and how quickly so that a replacement can be introduced in a timely manner.

Predicting crack growth in materials with finite elements can seem more art than science.

As an example, in some codes you may need to construct a very precise ‘rosette’ mesh at the crack tip.

A series of angular perturbations to the crack tip node are then simulated to look at the energy release resulting from extending the tip with the assumption being it moves in the direction of the greatest energy release.

Adaptive Meshing

Coping with Large Strain and Large Deformation in FEA

One of the challenges of analysing the performance of large strain materials like rubbers and synthetic elastomers is how the finite element mesh distorts as the part deforms.

You may well start out with a lovely mesh where all your elements meet your quality standards, but as the part distorts the element quality gets worse and worse until it can actually prematurely end the analysis because of excessive distortion, let alone give you poor results.

This is not an uncommon problem.

Random Vibration Fatigue

In a previous article I discussed using random analysis to predict failure of components in a vibration environment. Random analysis is a quick way of ensuring that statistically the maximum stress due to a vibration loading will not exceed a set level, but the most common mode of failure in such an environment is not due to one single load spike but due to the summation of damage from all the load cycles – known as fatigue failure.

Classically fatigue failure due to a transient load was performed quasi-statically. A known load history was combined with stresses from a unit load in the FEA model to create a stress time history. Rainflow cycle counting was used to evaluate the stress cycles and then damage calculated from these using classical theories like Goodman and summed using Miner’s rule. There were problems with this method though.

.png?width=139&height=70&name=DTE-Logo%20(4).png)