Company Restructuring & Software Licencing

Since the start of the COVID-19 crisis companies in the aerospace design and manufacturing sector have been particularly affected by the economic impact of the disruption to worldwide economies. Some have seen their orders and revenues drop immediately by sometimes 50% driven by the reduction in production of new aircraft.

These companies have had to quickly reduce costs and take advantage of any state support.

However, those with low cash reserves have seen the need to restructure through some form of merger, sale or even some type of insolvency process.

Topics: Dassault Systemes, #HowCanWeHelpYou?, Hexagon MSC Software

Space Technologies - solutions with Heritage

NASA Structural Analysis Code* was just the beginning .....

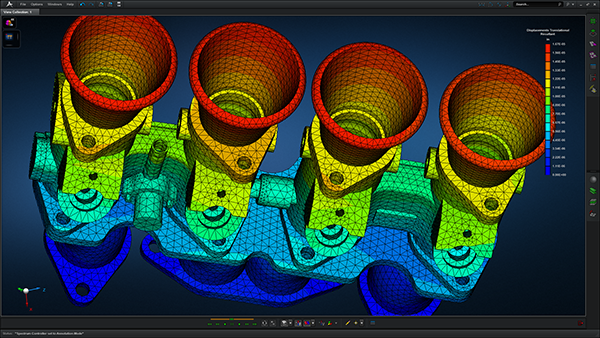

MSC Software has been a key partner to the Space Industry since the 1960s. Many people associate MSC only with Nastran, which is the keystone of their product set, but through a process of development and acquisition, they have developed a portfolio of tools that are used across a number of domains within engineering simulation in the Space Industry.

Topics: Finite Element Analysis (FEA), Aerospace, Hexagon MSC Software, space techologies

Improve composite FEA process AND get manufacturing output

How to improve your composite FEA process AND get manufacturing output as a side benefit

When working with laminated composites it is important to consider the effects that draping the pre-pregs has on the orientations and thickness that get used in finite element analysis.

Laminate Modeller is a plug-in tool for MSC Patran that does this fundamental job, but offers so much more.

Topics: Various - CAD CAM FEA PLM, Finite Element Analysis (FEA), TechTips, Hexagon MSC Software

How to define composites in MSC Apex

MSC Apex is the quick-to-learn, easy-to-use, intuitive Finite Element Modeller from MSC Software.

Defining and using laminate materials is part of the base license and uses a zone-based methodology for managing the stacking sequence.

The video demonstration is a short walk-through on how to go about applying laminate material (composite) properties to a mesh in MSC Apex, illustrating how a panel has its zones defined, and how you can interrogate a laminated model to understand the material definition.

New Space ... New Horizons

New Space – the commercial space industry driven by private organizations – is making giant leaps in space tourism, exploration and satellite technology. Europe, the USA, China, India and Israel are among the countries that stand to gain as innovative projects promise benefits such as insights into weather patterns and climate change, better communications networks, and geographical data analytics to help farmers improve crop yields.

Topics: Aerospace, #HowCanWeHelpYou?, space techologies

A New Year Begins ...

All the team at Desktop Engineering would like to wish all our customers and suppliers best wishes and good fortune for the new year of 2021.

We’ve entered it again with similar lockdown constraints we all worked through 9 months ago. Looking back at that time there was considerable doubt and uncertainty over the outcome.

However, our team, along with support from our loyal customers, have worked through the challenges and arrived in this New Year with a remodelled way of working to meet these renewed constraints.

Topics: #HowCanWeHelpYou?

Value of PLM for small businesses in 2021

It is a very common feeling when the acronym “PLM” is mentioned that one would think of a large enterprise or business. I wouldn’t argue but, this acronym or infrastructure is not only for large companies. The acronym underlines a process in which currently all companies irrelevant of size or annual revenue undertake in either a manual or semi-manual process.

PLM – Product Lifecycle Management

⇒ Is there a product that is developed, designed to manufacture, installed,and maintained that does not have a managed lifecycle?

Topics: 3DEXPERIENCE, Product Lifecycle Management (PLM), SOLIDWORKS

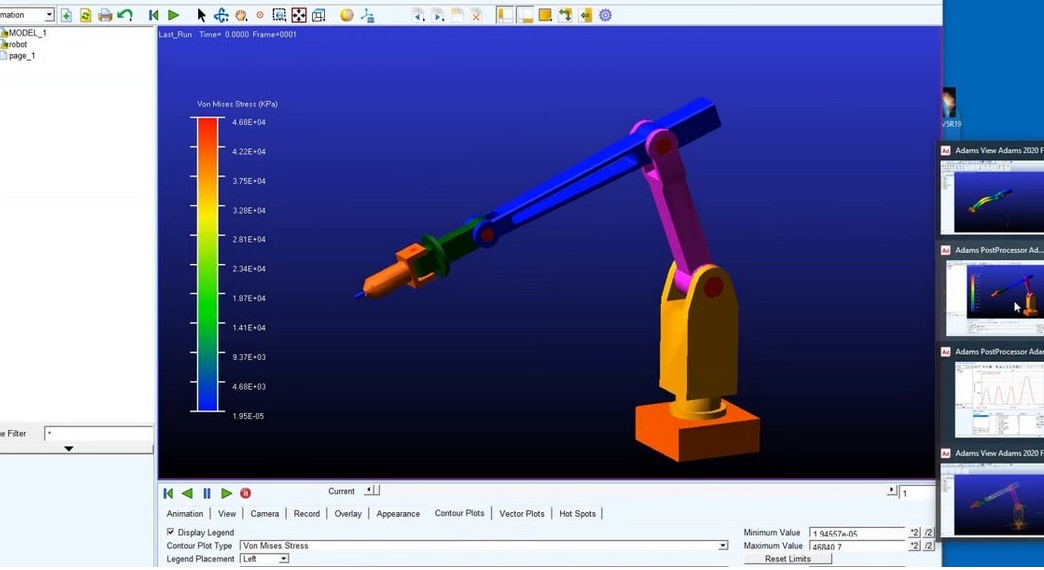

How & Why with Adams Flex

How To and Why To use Flexible Members in Mechanical System Design

System dynamics is very important in the design of mechanisms – ignoring dynamic effects and flexibility in your system by simulating mechanisms using simple kinematics such as the tools in your CAD system, can lead to problems in behaviour downstream - as this short video illustrates.

Topics: Various - CAD CAM FEA PLM, Finite Element Analysis (FEA), Hexagon MSC Software, CAE Tools

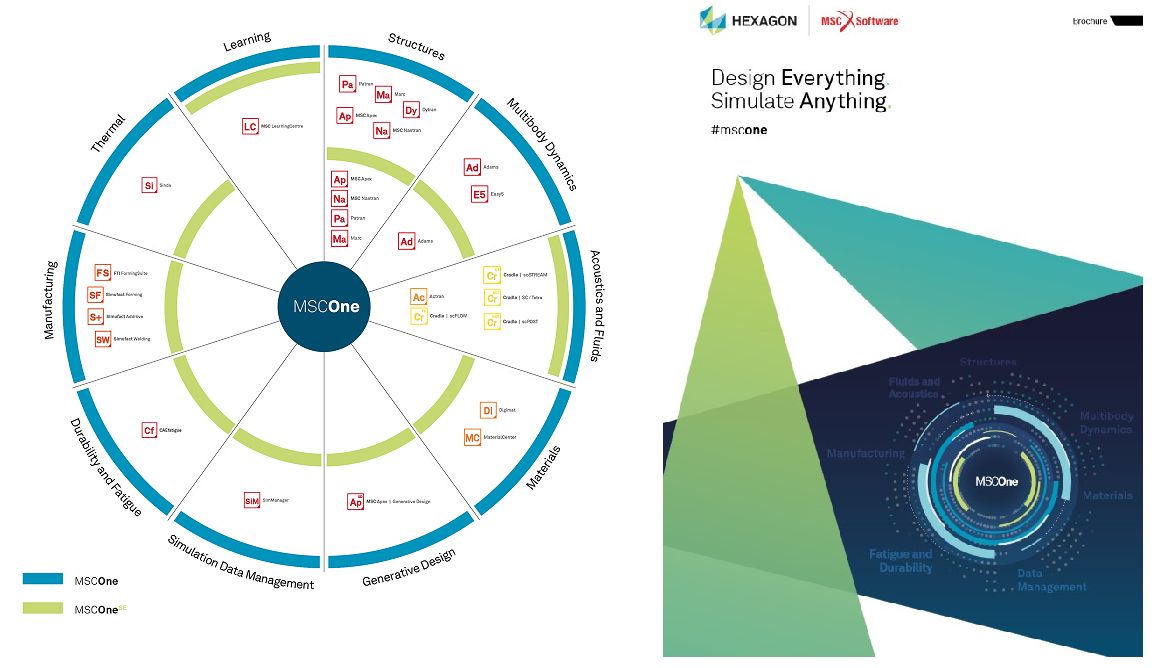

Unboxing MSC One

The MSC One Method

With MSC Software's subscription based token system, you receive a pool of tokens. Your tokens are checked out from the pool and are used to access and run a full range of CAE solutions available under the MSC One licensing system from MSC Software. Each individual software item requires a certain number of tokens to run. After each use, your tokens are returned to the pool for other use. There are dozens of software items available under MSC One.

Topics: Various - CAD CAM FEA PLM, Finite Element Analysis (FEA), Hexagon MSC Software, CAE Tools

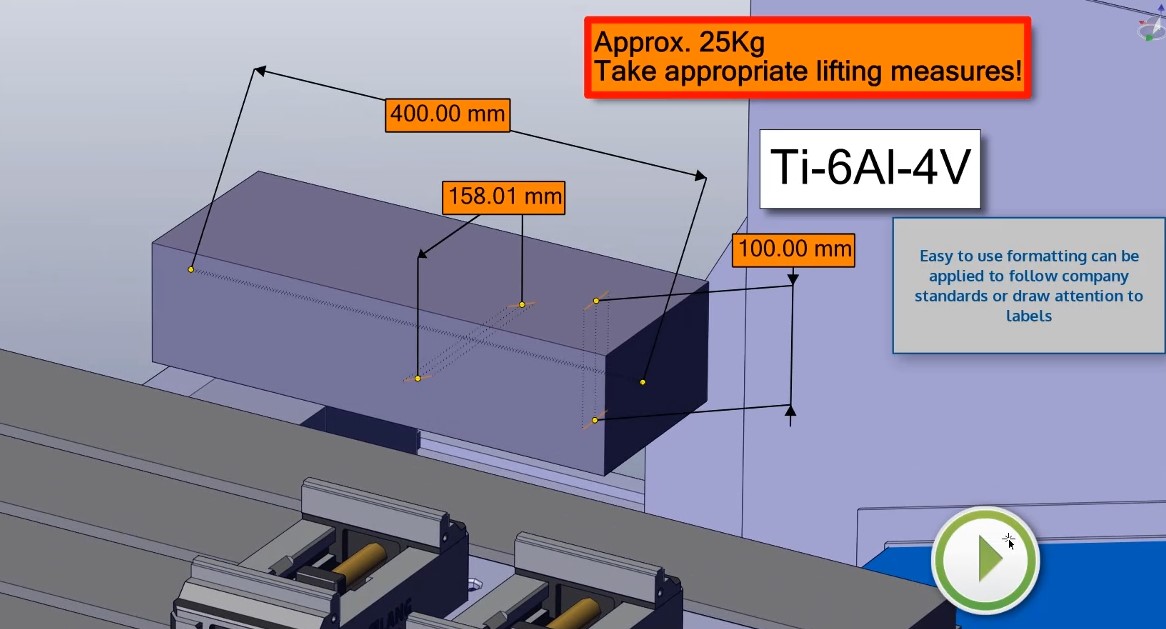

Digitizing Shop Floor documentation with CATIA Composer

Wide Ranging Capabilities

Whether your company specializes in machining, assembly or maintenance, CATIA Composer offers wide ranging capabilities to produce animation, still images or technical illustrations.

Topics: CATIA, TechTips, Manufacturing

.png?width=139&height=70&name=DTE-Logo%20(4).png)